Temples

Castello Officine srl has been working in the textile machinery sector since 1948. Following the long experience has become a high precision company, with the aid of particulary sophisticated machines developed after years of research, produces exclusive models of temples which are appreciated the world over. The production is meeting a wide range of requirements. The temples can be used on the entire range of fabrics currently existing (fine and course fabrics, fabrics with few picks per cm and very compact fabrics, with low shrinkage or with high shrinkage) can be adapted to suit any model of weaving machines present on the market.

The Officine Castello temples are a guarantee for:

LONG WORKING LIFE MODELS FOR ALL TYPES OF FABRICS CAN BE ADAPTED TO ALL WEAVING MACHINES

The Temple must be chosen according to the fabric to be produced. We can help you to choose the most suitable type for your requirements and we can supply special temples to meet your specific request. We normally catalogue our temples with a letter corresponding

to the type of fabric to whitch they are suited.This classification remains the same for all brands and models of loom on which they can be used.

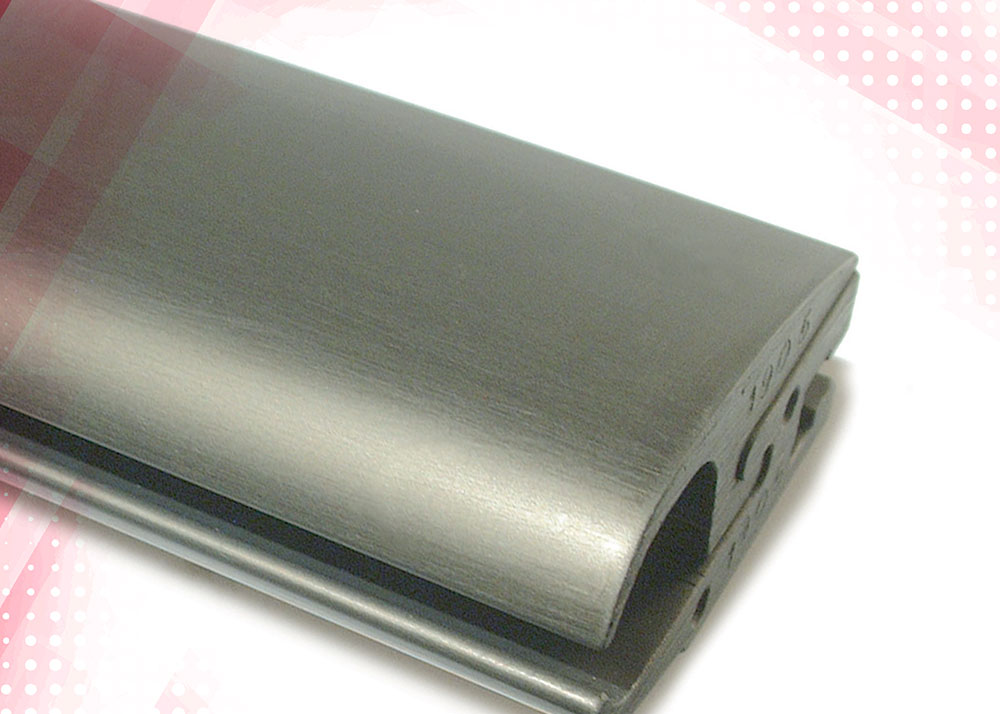

Full width temple

Full with Temple series AA

full widthtemple’savantages

· lowerwarptension

· no more damages from standard temple

· no more fabricdeformation on standard templeworking area

· higherweftinsertions

· quickmaintenance

Application fields

For all the fabricsthatneed an exactgeometry and high weftdensity

Exemples: tecnicalfabrics, airbag, filter, silk, fine wool, automotive , denim

Our full widthtempleissupplied complete of

· 1 upperprofile

· 1 lowerprofile

· 1 rod stopper left

· 1 rod stopper right

· Holding brackets

· Screws ,spacer an additionaccessories

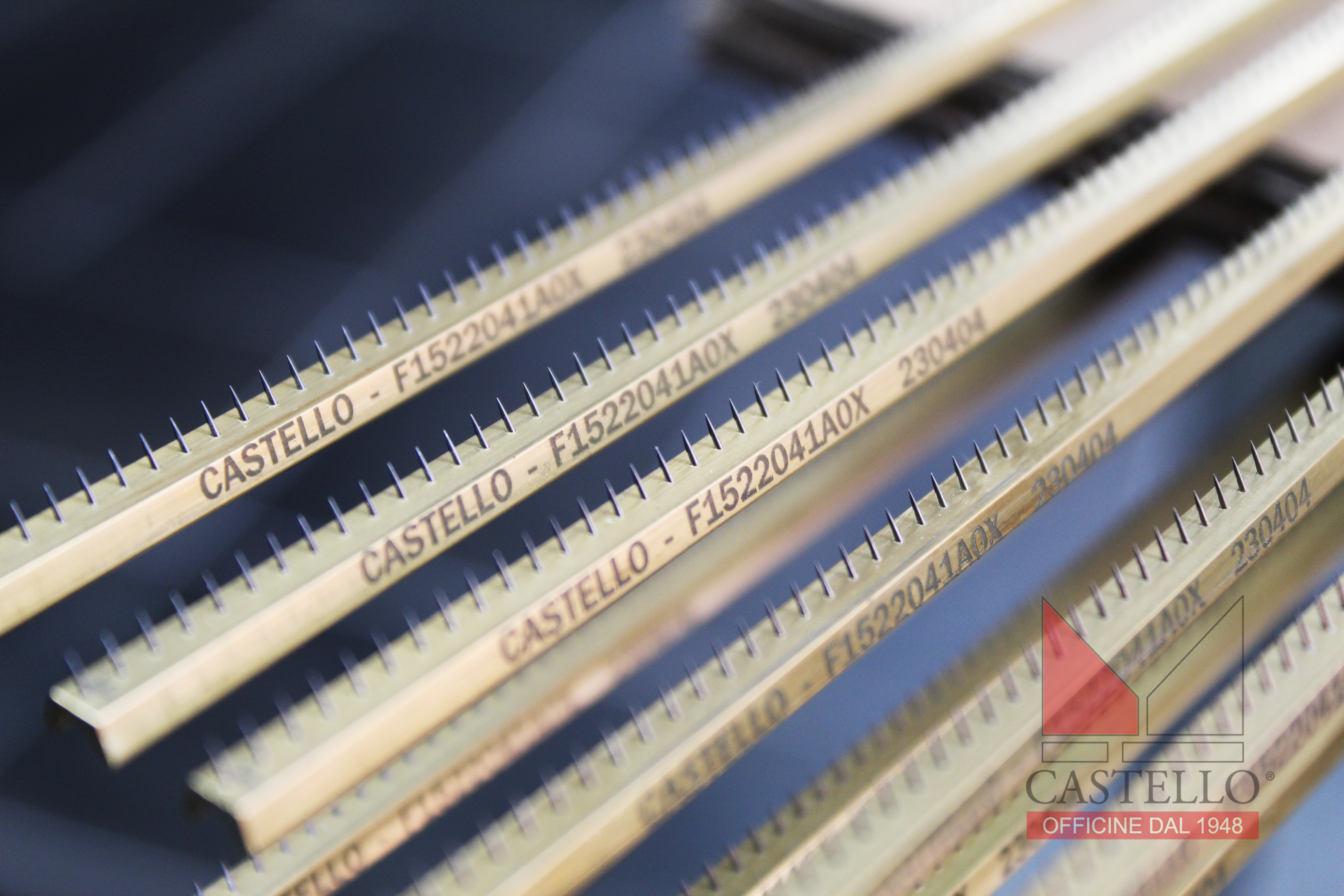

Fibrillating

Castello officine srl produce high quality FIBRILLATING BARS

The bars are assembled in our factory in Italy, all the raw materials and pins are made in germany. With our vision system we can guarantee a 100% pins control. The use of this technology brings many advantages, including low-cost production, increased flexibility, and higher precision of the finished product. That allows numerous technical possibilities:

· from 3 pins cm up to 50 pins cm

· pin diameter 0.38 mm up to 0.62 mm

· pin height from 0.2 mm up to 6.00 mm

· Inclination 15 and 30 degrees

· bars lenght till 1600mm

· pins on 1 row or 2 rows, staggering from 1up to 8

We can supply special bars on customer request. We can handle batches of small, medium, and large quantities.

Needle stripes

Castello Officine srl produce needle bars for composite machines

The bars are assembled in our factory in Italy,the pins are made in germany.

With ourvision system we can guarantee a 100% pins control.

We can produce different standard of needle stripes

We can supply special bars on customer request

CNC Turning

Castello Officine srl is a dynamic company that performs turning of high precision parts for third parties.

Thanks to the CAD / CAM technology we can carry out very complicated processes and provide timely estimates.

We are able to carry out mechanical work on a wide range of materials and any lot.

Our technologically avant-garde machinery allows us to position ourselves as a highly competitive company in the field of precision machining for third parties.

Vibratory finishing

We carry out Vibratory finishing and Barrelling with the use of abrasive and ceramic inserts that allow us to remove the burrs present on parts coming from shearing, turning and casting molding.

The development of innovative techniques and the use of new materials allow us to carry out non-aggressive vibratory finishing processes capable of obtaining low roughness and highly reflective surfaces.

Vibratory finishing is typically used to remove substrate residues, burrs and imperfections generally due to processing, it is particularly suitable for giving a uniform surface finish to a large number of pieces.

Quality

Our strength is Quality

The strength of the product we supply is to be sought in the quality and frequency of checks carried out throughout the production process of the particular itself.

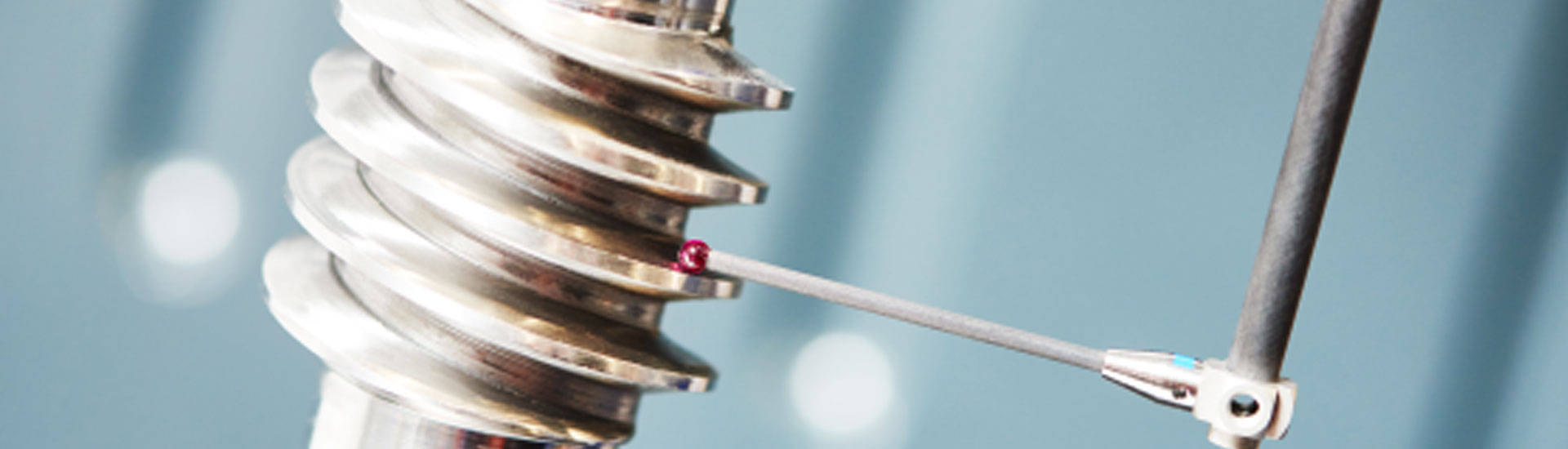

The controls during the processes are performed by specialized personnel through the use of a state-of-the-art metrology lab equipped with countless measuring instruments working in an air-conditioned environment.

We work according to the UNI EN ISO 9001: 2015 certified Company Quality Management System by ACCREDIA.

The technological innovation of recent years has allowed us to take a further step forward on the quality that we can guarantee to our customers. In fact, at the request of the customer, we can issue qualitative reports even on 100% of the details.