The strength of the product we supply is to be sought in the quality and frequency of checks carried out throughout the production process of the particular itself.

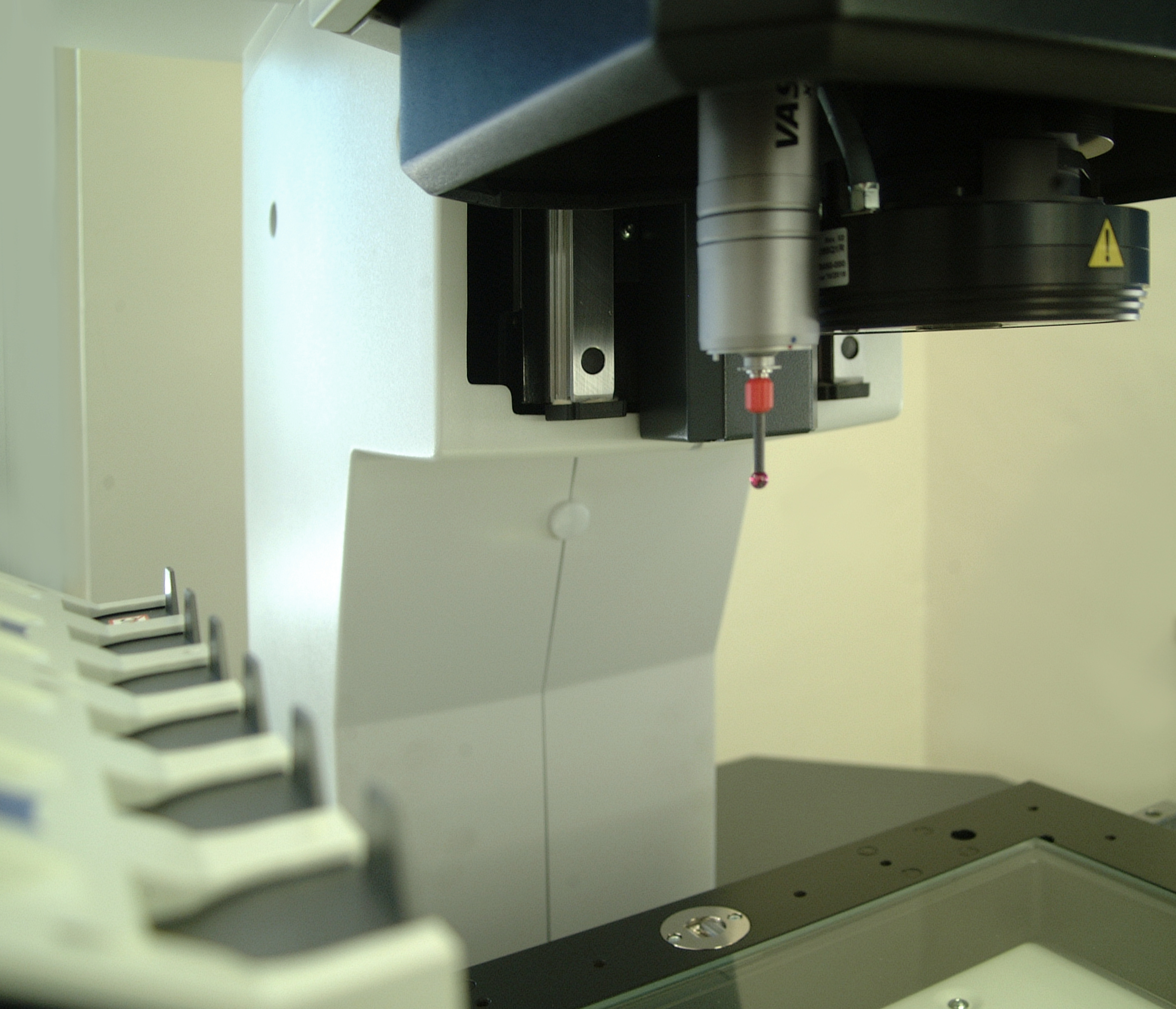

The controls during the processes are performed by specialized personnel through the use of a state-of-the-art metrology lab equipped with countless measuring instruments working in an air-conditioned environment.

We work according to the UNI EN ISO 9001: 2015 certified Company Quality Management System by ACCREDIA.

The technological innovation of recent years has allowed us to take a further step forward on the quality that we can guarantee to our customers. In fact, at the request of the customer, we can issue qualitative reports even on 100% of the details.

Castello Officine performs measurements on behalf of third parties and offers this service both for single pieces and for the series.

Thanks to our metrology room we are able to offer services for the following measurement tasks:

Our work is always certified by a report that is issued to the customer

Castello Officine also has a state-of-the-art metrology room equipped with countless measuring instruments working in an air-conditioned environment:

ZEISS O-INSPECT 322 inspection machine Optical / Tactile

Anthropomorphic arm FARO Tactile measurement

· 1 set of Jonson blocks

· 1 roughness tester

· 1 durometer

· 1 bore meter

· internal and external micrometers

· Leica microscope